|

|

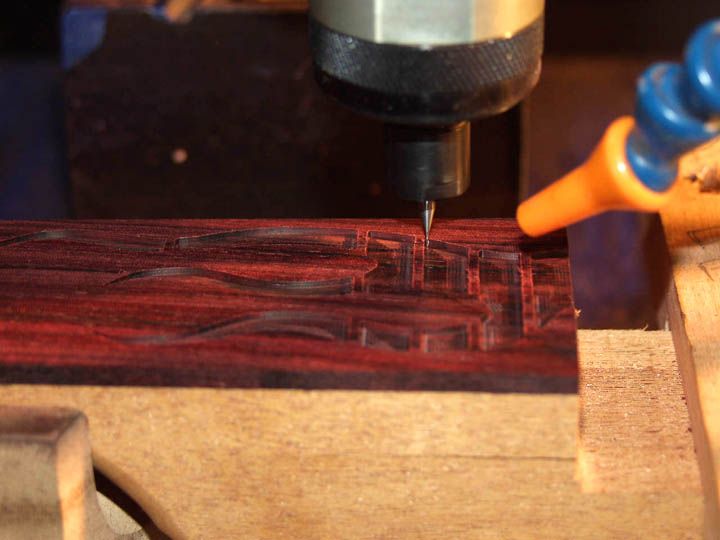

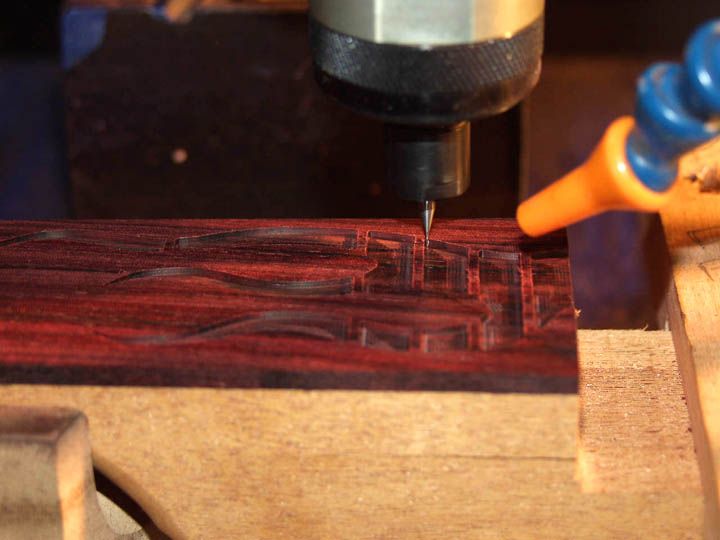

| Here the flame inlays are getting cut. Takes

forever but they are within a few ten

thousandths. |

|

|

|

| The fretslots are notched through the pearl or

if the pearl extends across the fretboard then wood is left for the frets to compress. |

|

|

|

|

|

| The fretboard is getting arched again to cut the

gold flush. At this point the hideous sanding begins. Files, sandpaper,

and steel wool to remove all the marks and get it ready to be buffed.

This takes forever. Tons of work to get it all smooth and ready to

buff. The fretboard and inlays will have a shine like chrome on them soon. |

|

|

|

| The fretslots are being cut here. That tiny

little endmill is only 20 thousands of an inch. That is

.020". It's about the size of a needle. These things

are expensive and they break if you look at them wrong. It takes a while

to do the fretslots but when they are done, they are within around a ten

thousandth of where I want them to be. That is like taking a hair and

dividing it 50 times. Now, get out your microscope and you can see how

accurate that is. That should be close enough. It cuts the fretslots

and arches the slots just like the fretboard. This leaves no air space

anywhere and should theoretically contribute to the Diablo's tone. |

|

|

|

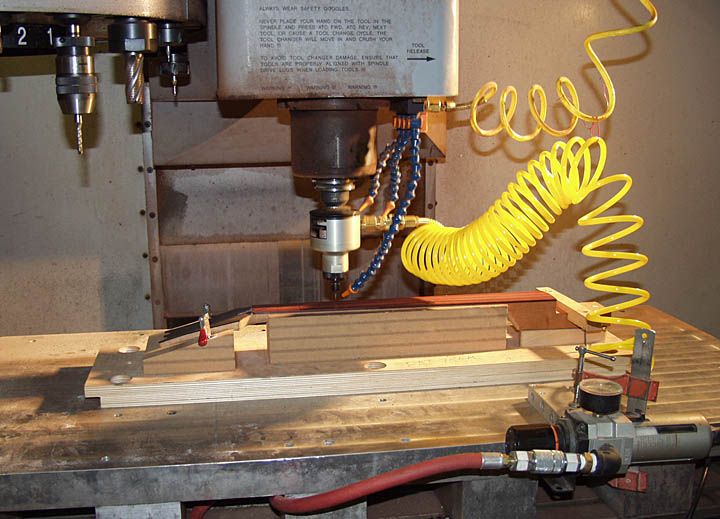

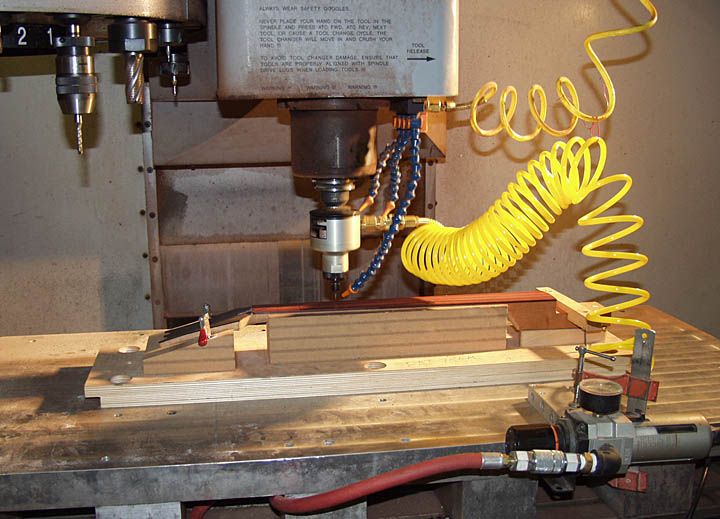

I had to get an air spindle to spin these

tiny endmills fast enough. This thing is so cool that I got another one.

They both spin at 40,000 rpm and are very quiet. I am devising a way to use

solenoids and air cylinders to make it so that the air spindles can ride

up and down on the side of the head. That would make a lot of cool noises too.

Kind of like Willy Wonka and

the Chocolate Factory. How do I keep

sawdust out of that chocolate river? Humm, have to work on that.

I also made an arbor

out of titanium to hold a saw blade. That will be really cool to mount

it sideways to do the fretslots. It is kind of scary at first because it hangs

out of the spindle with this coiled air hose and regulator hooked up to

it. Once, the spindle came on at 10,000 rpm and threw a fit! Busted air

lines, a loose air hose spraying mahogany sawdust everywhere and this

air spindle hanging in there and spinning at 10K rpm! After I got it

stopped, I couldn't seem to get near that machine for about an hour.

Kind of skiddish. |

|

|

|

I call this machine "Slacker" because

he enjoys sitting and relaxing so much. That is my fault so I can't

blame him. Here Slacker is doing

fretslots with that air spindle hooked up to him. He is probably very

confused right now because he is actually working and wondering "

how did this happen?". He seems to rejoice

in sitting still and observing me. It's fun to surprise him and make him

work for hours at a time. He can't complain because he has no vocal

chords. Very obedient too. He especially delights in following instructions when I

give him the wrong ones. Oh the joy he finds in taunting me.

I can never blame him for messing something up.

He just doesn't do it unless I tell him too. Other than that, Slacker is

amazing! Every time he does something, I am still in awe of his accuracy

and what he can do. Now, if I could just get him motivated.

|

|

|

|

|

|

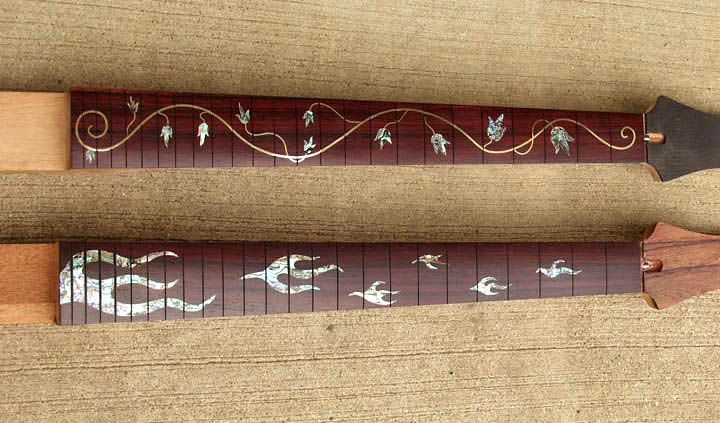

| In these two pictures, the flame inlay is being

cut. This inlay is the one that I said that I would never do again.

Well, I worked on the inlay for days and made it so that this is one of

the most stunning inlay ever. Guess that I will have to keep doing it

now. It looks really hot rod like. |

|

|

|