|

||

|

Here is a nice green Diablo sporting the Driskill Tremolo.

This page might take a while to load, but there are some cool pictures of the tremolo and some of how it is made. It might be worth the wait.

|

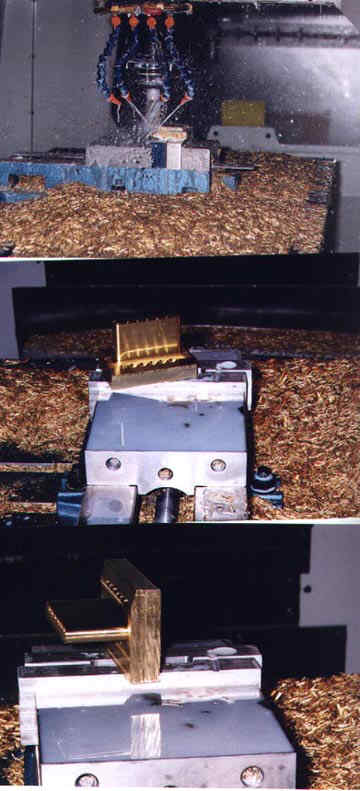

| Here are some of the

partially done tremolos. See the chunks of brass behind them? That was one

120 pound piece of brass. I bandsawed them to rough size like you see in

the picture. That wasn't easy. At that point, the fun begins. I have a ton

of work to do from here. These are only about 1/3 of the way done.

This represents hours and hours of work.

I only use brass because it sounds so good. It is so resonant. Guess that is why they make bells with it. Most high quality trems and bridges are made of steel. They are not made of brass because it is so expensive. Brass costs about $4.00 a pound if you get a lot of it. Steel is dirt cheap. It is around 0.13 cents a pound! You can quickly see why nobody seems to use it. Just like everything on a Driskill Guitar, I use only the best no matter the cost. |

|

|

This is really cool! Here

is one of the trems being cut. It takes forever and tons of tools. I had

to make twelve different sets of jaws just for the vise. Each set of jaws

has the shape of the trem up until that point cut into them. The tremolo

starts off as a block and slowly metamorphosis's into the looker you see

here. It takes a lot of steps to get it done!

Most trems are made of pressed steel or die cast. You will note that almost all trems are made in two parts. That is the easy way. But you can probably tell, I never take the easy way. I do whatever it takes to make the best guitar on the planet. It is always much more expensive for me, but that is the only way I will do it. Nothing gets on a Diablo unless it is the best thing out there. That is why I had to make these. There wasn't anything good enough available. Once all of the setups, vise changes, and cutting is done, (It took me about a month to make thirteen of these, but that was the first time. Maybe it will get easier. I hope so.) I have a brass bridge that is very rough looking. I have to hand sand forever to get rid of the toolmarks. When I get rid of those, it is buffing time. Metal is mean. You do these tremolos and pickup rings, and every time you look at your hands you find about a hundred more tiny cuts all over them. You don' t even know where they came from! They just keep appearing. Better stop looking at my hands. I then start the hideous process of buffing the metal. This is nasty work! The trems get really HOT! You also find yourself covered in this black soot. I didn't get a college degree for this! But, it has to be done. I have to go through a number of buffing compounds and buffing wheels to get the trems ready to plate. When they are done, they look like they are already plated. They look like a mirror. Not a scratch, pit, or anything anywhere. Then they are off to get plated.

|

| Here is one of the saddles that I made for the peizo inserts. II had to mill these tiny pockets and drill a very small hole for the wire. Also the adjustment screws are different. Once again, I had to make these because there wasn't anything good enough for my guitars when someone wanted the L.R. Baggs system. I had to make my own saddles and special tremolo bodies with the right pockets and slots. |  |

|

Here is a chrome one with the peizo system in it. It has slots for the wires and a recess on the trem body for the sum board. |

|

Looks pretty slick, huh? |

|

|

I make the screws too. Well, I bought 5000 of the right size screw. Then I had to cut the correct beveled notches into them one at a time. I will have some more pics up soon. |

| Here is a shot of the back of the body of the trem. I even engraved my logo into it. Kind of like signing a painting when you are done. This way you know that you are getting a Driskill tremolo and not some lame, pressed or cast two piece, bolt together... "they'll never know"...., piece of junk. |  |

|

I noticed that most of

the pictures that I have are of gold ones. I will put some chrome ones up

soon. This is 24 karat gold plating. It is also really thick so that it

won't wear off.

On the chrome ones, I get this show chrome done. It is the best looking chrome you can get. It has a slight, bluish cast. Like they put on tricked out Harleys or show cars. It is very nice. Chrome is by far the most durable plating. It is so hard that it doesn't wear off. For gold, I use the best plating available, and I have them put it on thicker than anybody else uses.. It is expensive to have this done, but, I don't want it to wear off like other gold plating. Still, gold is, I think, the second softest metal, so it will not be as durable as chrome. Just depends on what you like and how you play. |

Hope that you like this. Let me know if you like this kind of stuff.

It's really hard to find time to do this, but I thought that you might

like to see some other stuff. Let me know what you would like to

see and I will try to put it on here. I do all of my website myself,

so as you can imagine, it is hard to find the time.